![]()

Since many energy sources are non-renewable, countries around the world are advocating for the use of renewable energy and even providing substantial subsidies. Combustible waste, as a readily available renewable energy source, is increasingly favored. Biomass energy, as a type of renewable energy, is attracting more and more attention. So, is there a type of equipment that can recycle and reuse waste materials?

Yes, Biomass Energy is currently one of the fastest-growing renewable energy sources worldwide, especially having great potential in replacing fossil fuels, reducing carbon emissions and promoting a circular economy.

Sources of Biomass Waste

Agricultural Waste

Post-harvest crop residues such as wheat straw and corn stover, which are rich in cellulose and other organic compounds, form a major component of biomass waste.

Byproducts from agro-processing, including fruit/vegetable peels, pits, and stems generated during food production.

Forestry Waste

Logging and timber processing byproducts like branches, sawdust, and bark.

Residual materials from forest thinning and management, such as small twigs and leaves.

Animal Waste

Animal manure, which contains high organic content.

Bedding materials (e.g., used hay, wood shavings) mixed with manure during farming.

Urban Organic Waste

Household food waste (leftovers, kitchen scraps).

Sewage sludge from municipal wastewater treatment plants, which retains organic matter.

How to Process Biomass Waste?

1. Biogas Production

Biogas power generation systems are widely used due to their mature technology and simple equipment. Compared to liquid fuels, biogas is easier to compress and store, making it a practical renewable energy source.

2. Gasification Power Generation

Biomass undergoes chemical reactions under anaerobic conditions in a gasifier, converting it into combustible gas (syngas) for power generation.

3. Production of Bio-Coal Briquettes

Bio-coal briquettes are a coal-like solid fuel that improves energy density, making them easier to transport and store. Raw biomass is processed into a suitable state and then compressed into briquettes.

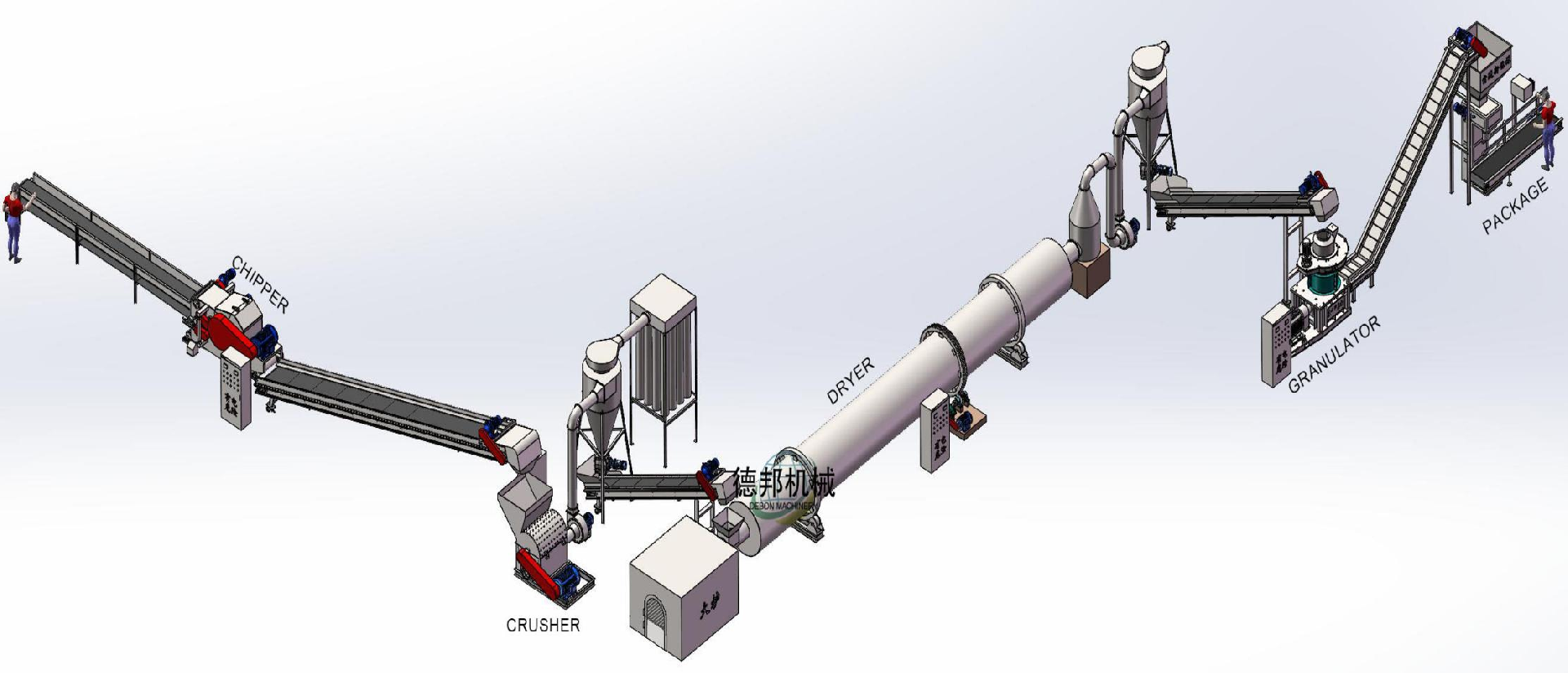

Bio-Coal Briquette Production Process

Step 1: Collection & Pre-Treatment

Collection: Biomass waste is gathered through specialized collection systems.

Sorting: Impurities (stones, metals, etc.) are removed.

Crushing: Biomass is shredded into small particles to increase surface area and improve processing efficiency.

Dehydration (if needed): High-moisture waste (e.g., food scraps) may require drying.

Step 2: Fermentation or Pyrolysis

Fermentation: Organic matter is decomposed by microorganisms under aerobic/anaerobic conditions.

Pyrolysis: Pre-treated biomass is heated in an oxygen-free environment to induce thermal decomposition.

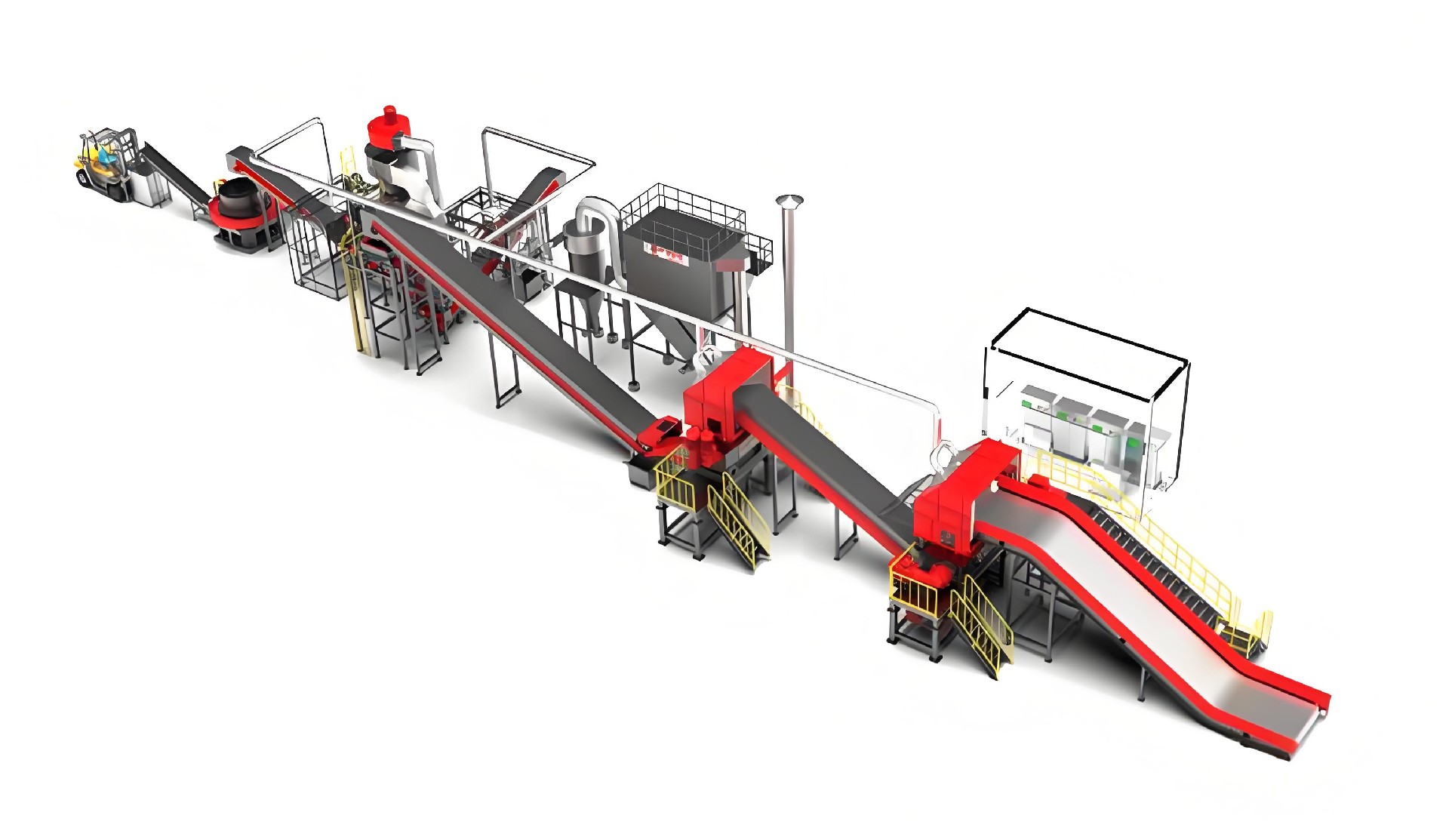

Step 3: Briquetting

The processed material is dried, mixed, and compressed into dense fuel blocks using:

Screw extruders

Piston presses

Ring-die pellet machines

The final briquettes have high density, good combustion performance, and are easy to store/transport.

Characteristics and Advantages of Fuel Briquettes

1. Characteristics

Density: After processing, the briquettes achieve a high density (1.1–1.4 g/cm³), making them easier to store and transport.

Calorific Value: Typically 16–20 MJ/kg, ensuring stable heat output.

Shape & Size: Usually 6–12 mm in diameter and 10–30 mm in length, making them compatible with various combustion systems.

2. Advantages

Environmental Benefits:

Converts biomass waste into valuable fuel, reducing pollution from open burning or landfill disposal.

Supports circular economy by turning waste into energy.

Energy Replacement:

Acts as a renewable alternative to coal and oil in heating, power generation, and industrial applications.

Enhances energy diversity and security.

Economic Benefits:

Waste treatment plants gain new revenue streams from briquette production.

Reduces waste disposal costs while creating a marketable product.

How to Turn Waste into Fuel Briquettes?

The process of producing bio-coal briquettes is simple. As mentioned earlier, only basic waste treatment is needed. But what qualifies as "well-prepared" raw material? It depends on two key factors:

1. Properly Sized Material

The biomass must have a suitable particle size for briquetting.

While binders are not required, a uniform particle size distribution ensures high-quality, durable briquettes.

2. Optimal Moisture Content

Too much moisture (e.g., >30%) → Poor compaction, cracking.

Too dry → Weak bonding, crumbling.

Ideal range: ~10–25% moisture (adjustable based on biomass type).

Bio-Coal Briquette Production Process

Raw Biomass Waste

⇒ Drying (sun-drying or industrial dryer)

⇒ Crushing (crusher/grinder)

⇒ Briquetting (briquette press)

Key Notes:

High-moisture biomass (>30%)? → Pre-dry naturally (cost-effective) before mechanical drying.

Our briquette machine features a flexible mold system, allowing easy switching between briquettes & pellets in the same equipment.

Applications of Biomass Fuel Briquettes

Industrial Use

Boilers, power plants (coal replacement).

Cement/steel industries (process heating).

Household Use

Cooking fuel (cleaner than charcoal).

Fireplaces, stoves (sustainable heating).

Why Choose Briquetting?

Waste → Wealth: Monetize agricultural/forestry residues.

Energy Security: Reduce reliance on fossil fuels.

Low-Tech & Scalable: Suitable for rural and urban setups.

Need technical specs (such as , machine capacity, moisture control methods)? Let me know!