About Biomass Pellet Production Line

Biomass pellet production line is designed for manufacturing biomass pellets from any type of raw materials,such as wood chips, rice husks, straws, grasses, bamboos, etc.In general, the manufacturing process of a biomass pellet production line includes 5 steps: crushing, drying, pelletizing, cooling, packaging. Of course it can be customized by your requirements, such as you can decide to choose fully automatic types, semi-automatic type.

Compared with a single biomass pellet machine, the biomass pellet plant system can complete the entire process from raw material processing to pellet finished product packaging.

What’s biomass: Biomass is inexhaustible and inexhaustible. It is a renewable energy source and the only renewable carbon source. It usually includes wood, forest waste, agricultural waste, plants, cities and Industrial organic waste, animal manure, etc. Biomass energy resources are relatively abundant on the earth, and it is a kind of harmless energy.

Suitable raw materials: There are many types of biomass, and the common biomass raw materials are agricultural and forestry waste. Subdivisions include sawdust, wood chips, branches, palm fruit bunches, palm shells, bamboo, bagasse, bark , furniture factory waste, building templates, wooden pallets, corn straw, wheat straw, rice husk, peanut shells, etc. Our current projects also involve the processing of plastic granules, rubber granules, paper granules, carton granules, tofu cat litter granules, bentonite granules, pyrolytic carbon granules, air purifier granules, plastic and biomass mixed granules and other products.

Applicable customers: Our business is based on meeting the requirements of forestry groups, energy companies, wood industries, and industrial as well as financial investors in biofuel pellet plants.

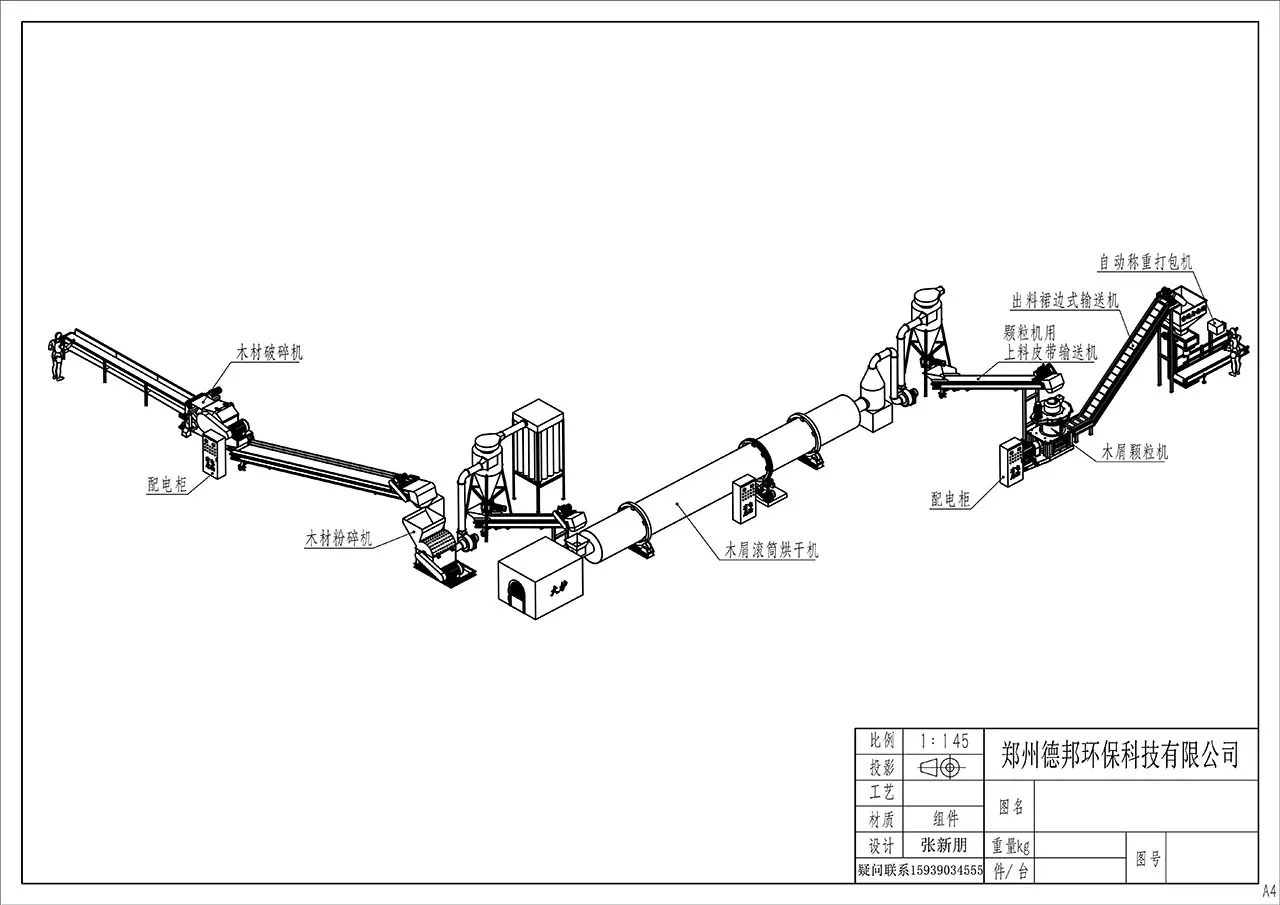

Process Flow Chart Details

Raw Material → 1. Crushing machine → 2. Drying machine → 3. Grinding machine→ 4. Pelleting machine → 5. Cooling machine → 6. Packing machine → Pellets

Equipment for Biomass Pellet Production Line

Ring die pellet mill is generally large wood pellet production equipment because of its large capacity as compared to small flat die pellet mill. It is usually used for industrial or commercial biomass pellet production. For example, investors who want to make pellets for sale or demand for large quantity biomass pellets would prefer to buy ring die pellet mill to build a complete biomass pellet plant.

Flat Die Pellet Mill is an ideal pelletizing machine mainly used for small-scale wood pellets production for home heating. Flat die pellet mill also has wide application in animal bedding plant. The raw materials for making biomass pellets are easy to obtain, like wheat straw, sunflower stalk, forestry wastes, wood chips, etc. Driven by electric motor makes it more energy-saving and environmental friendly.

Comprehensive Wood Crusher which is specifically designed for wood crushing, boasts high efficiency and reliable performance. The chipper is made up of several systems, including a feeding system, a crushing system, a drive motor, a discharge system, a hydraulic station system, and an electrical control system.

Rotary drum dryer is your best choice to dry biomass materials of high moisture content and produce high quality biomass fuel. Biomoass materials go through dryer can improve biomass fuel efficiency of 5-15% and lower down emission. It can be used for drying a wide range of biomass materials such as alfalfa, straw, sawdust, marigold, wood shavings, manioc waste, bagasse, colza cake and leaves, etc.