RDF Briquette Machine Introduction

Biomass briquette machine is one equipment which use fiber materials like smashed straw (within 50mm) or sawdust with moisture 12-25% as raw materials. By spindle rotates to drive the pressure roller to rotate, the machine produce centrifugal force to press the material from the die hole. The machine produce wood briquette with output size of 30mm.

Material Mastery

-

Plastic waste

-

Wood waste

-

Domestic garbage

-

Waste paper

-

Fabric Waste

-

Plastic Solid Waste

-

Plastic Bags Waste

-

Paper Mill Waste

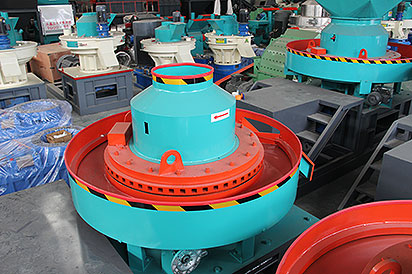

RDF Briquette Machine Gallery

RDF Briquette Machine Features

Easy to operate, convenient to use, high automation, less labor and high efficiency.

Adopt double roller structure, main shaft forcing evenly, machine running smoothly, reduce power consumption.

Die and roller are made of special alloy material, wear-resistant, pressure resistant, high temperature resistant, can continuous work without deformation, service life is 3-4 times than original ones.

The equipment adopts full automatic oil filling mode. The whole time supplies oil regularly, saving energy, time and greatly improving the service life.

Equipment for a wide range of materials: crop straw, sawdust and other fiber agricultural and forestry waste.

RDF Briquette Machine Technical Specifications

| Model | Power(kw) | Capacity(t/h) | Dimension(mm) | Moisture of raw material |

| 9JY-2000A | 55kw | 1.2-1.5 | 3000×1350×1870 | 15%-25% |

| 9JY-2600 | 75kw | 1.5-2.5 | 3040×1400×1900 | 14%-25% |

| 9JY-3500A | 110kw | 2.5-3.5 | 3500×1600×2200 | 14%-25% |

| 9JY-4500A | 132 | 3-4.5 | 3550×1670×2300 | 14%-25% |

Note: Technical specifications may change without notice due to ongoing technological advancements.