About Waste Paper Pellet Production Line

LONKIA's tomato peeling solution utilizes cutting-edge steam peeling technology, which involves the instantaneous release of high-pressure steam to rapidly separate the tomato skin, significantly enhancing peeling efficiency while ensuring the integrity and texture of the flesh. This solution is suitable for producing various tomato products, meeting the market demand for efficient and high-quality tomato processing technology.

Efficient Peeling

By employing high-pressure steam technology, the solution swiftly removes the tomato skin, making the peeling process more expedient and efficient.

Preservation of Flesh Integrity

Steam peeling technology precisely targets the tomato skin without damaging the internal flesh.

Retention of Nutritional Content

By precisely controlling the temperature and duration of steam application, the solution removes the tomato skin while retaining its nutritional content.

Energy-saving and Cost-reducing

During the steam peeling process, there is no need for extensive water resources or chemical agents, making it environmentally friendly, safe, and cost-effective in production.

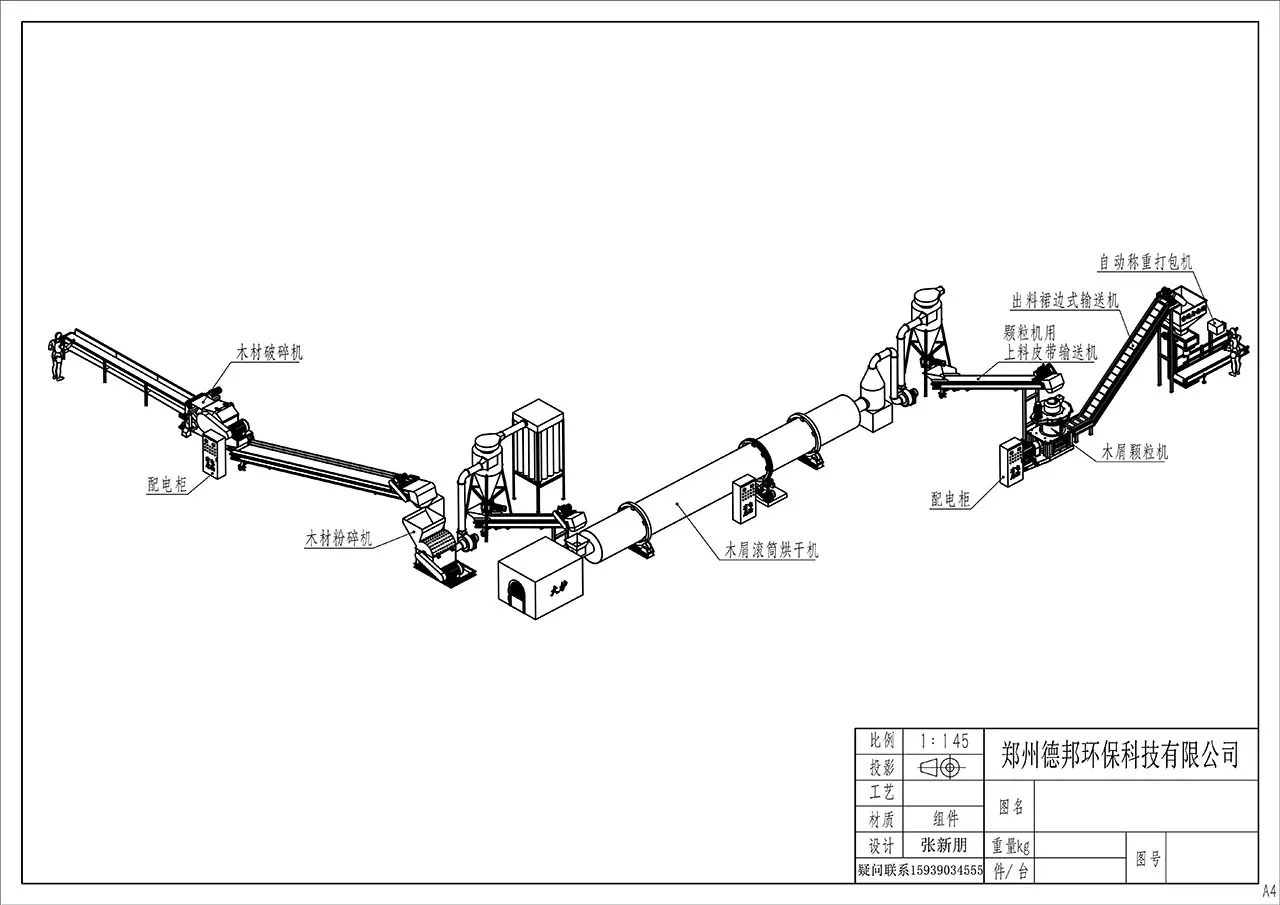

Process Flow Chart Details

Equipment for Waste Paper Pellet Production Line

Ring die pellet mill is generally large wood pellet production equipment because of its large capacity as compared to small flat die pellet mill. It is usually used for industrial or commercial biomass pellet production. For example, investors who want to make pellets for sale or demand for large quantity biomass pellets would prefer to buy ring die pellet mill to build a complete biomass pellet plant.

Flat Die Pellet Mill is an ideal pelletizing machine mainly used for small-scale wood pellets production for home heating. Flat die pellet mill also has wide application in animal bedding plant. The raw materials for making biomass pellets are easy to obtain, like wheat straw, sunflower stalk, forestry wastes, wood chips, etc. Driven by electric motor makes it more energy-saving and environmental friendly.

Comprehensive Wood Crusher which is specifically designed for wood crushing, boasts high efficiency and reliable performance. The chipper is made up of several systems, including a feeding system, a crushing system, a drive motor, a discharge system, a hydraulic station system, and an electrical control system.

Rotary drum dryer is your best choice to dry biomass materials of high moisture content and produce high quality biomass fuel. Biomoass materials go through dryer can improve biomass fuel efficiency of 5-15% and lower down emission. It can be used for drying a wide range of biomass materials such as alfalfa, straw, sawdust, marigold, wood shavings, manioc waste, bagasse, colza cake and leaves, etc.