Project Info

8 tons of palm silk pellet production line in Philippines is composed of 4 DB560 biomass wood pellet machine, the output of each pellet machine is 2 tons per hour. Palm oil production is an important industry in Southeast Asia. After the palm matures, the fruit is separated from the stem, leaving the empty fruit string (EFB) as a waste. Millions of tons of EFB are produced every year, and Research on the possibility of using this waste is also ongoing.

Main Equipment

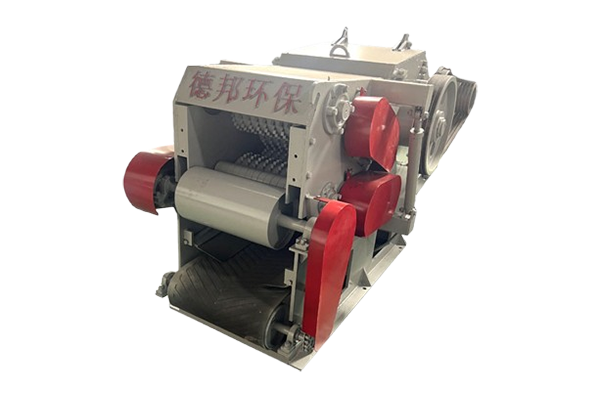

The wood integrated crusher is mainly used for crushing large diameter wood materials such as tree stumps, roots, trunks, all kinds of branches and other wood, but also can be used for baling straw crushing, large wood integrated crusher has the advantages of rapid feeding and high efficiency. Hydraulic material box turning device, can be in need of maintenance or knife change, large angle turning after part of the exposed operation is convenient.

Wood pulverizer is a kind of mechanicalequipment specialized in crushing andpulverizing all kinds of wood raw materials(such as logs, branches, trimmings, waste woodetc.) into smaller size materials.

Drum dryer is a kind of equipment used for drying operation, one machine can be used for many purposes, this equipment can use electricity, natural gas, biomass pellets or coal as the heat source, and dry the material by electric rotating and stirring.

Biomass pellet machine, alias: wood chip pellet machine, fuel pellet machine, sawdust pellet machine, straw pellet machine and so on. Biomass pellet machine is suitable for processing all kinds of biomass roots, stems, leaves, waste templates, bamboo and wood trimmings as well as waste wood furniture into high-density fuel pellets after processing. The equipment has a beautiful appearance and is now upgraded to the eighth generation, which reduces the footprint of the host body, has a reasonable structure, is easy to operate and has good molding effect.

Biomass pellet cooler is the key equipment in the production process of biomass pellets, mainly used to cool down and cool down the high temperature biomass pellets that have just been produced, so that they can reach the appropriate packaging, storage and transportation conditions.

Automatic baler is the key equipment to realize automatic packaging in biomass pellet production line, which can significantly improve the production efficiency and packaging quality.